Some Known Factual Statements About 24??media

Some Known Factual Statements About 24??media

Blog Article

Not known Details About 24??media

Table of ContentsAn Unbiased View of 24??mediaEverything about 24??mediaThings about 24??mediaOur 24??media DiariesUnknown Facts About 24??media

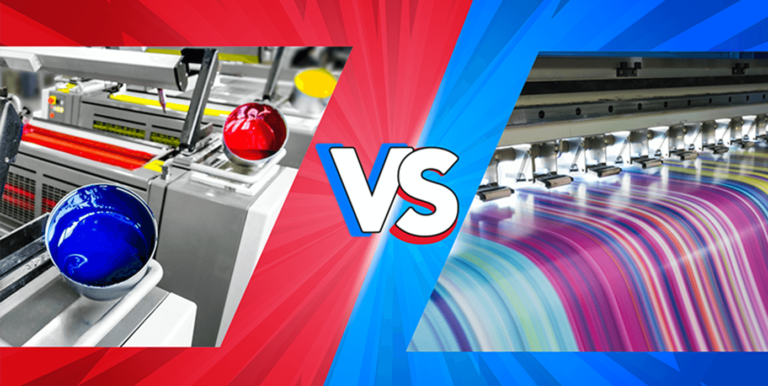

Offset, gravure printing and flexography are one of the most common sorts of conventional printing in the packaging area and each entails moving the photo from a plate to the surface area. To do this, first the plate needs to be developed, and it is the development of these plates that take time, and set you back money.According to PMMI, digital printing enables brand names and manufacturers to react promptly to customer needs while boosting the supply chain, decreasing warehousing expense and waste, and appreciating faster time to market. That all sounds excellent, yet just how does this innovation do all that? The major differentiator of these technologies is that there are no set up fees and no plates with electronic printing.

According to Wikipedia, the greatest difference between electronic printing and traditional methods such as lithography, flexography, gravure, or letterpress is that there is no need to replace printing plates in digital printing, whereas in these analog printing techniques home plates are repetitively replaced. This results in quicker turnaround time and lowers expense when making use of digital printing.

Fast production implies getting your product to market quicker. It also means it's less complicated and faster to make adjustments later, when you alter a recipe, include a SKU, or produce seasonal product packaging. Digital printing is very versatile, so it's simple to make adjustments to the plan design swiftly. Everything returns to the plates.

Examine This Report on 24??media

More stock can imply even more waste down the road. With conventional printing approaches, short-run printing is simply not feasible. Due to the fact that a terrific style can make or break your product, digital printing constantly develops top quality, clear and colorful graphics each time. Digital printing on adaptable pouches adds the intense, dynamic, and specific graphics that almost bid customers to connect and touch them.

Packing ... Are you acquainted with the advantages of electronic printing? Keep reading to comprehend when digital printing can be the very best possible service for your business. Do you know why electronic printing has become the preferred option of some companies? Both offset and electronic printing have their area in the printing market.

In this post, we will certainly talk about the benefits of digital printing to help you much better understand if digital printing is simply what you need. Simply placed - digital printing prints product directly onto the paper.

Some Known Factual Statements About 24??media

As digital printing continuously develops, it supplies much more opportunities and greater output high quality every day. Sometimes, the print high quality can be as high regarding offset printing. As years go by, digital print is becoming much more available, with enhanced rate and top quality. This is just the reason printing firms are including electronic printing to their offer.

For countered printing, if any kind of mistake goes unnoticed prior to creating home plates, there will be a high cost of developing a brand-new one. With electronic printing, this is not the situation (Wallpaper). Although everybody always wishes there will be indisputable, understanding the expense of correcting them if they happen is always an excellent idea.

This implies each and every single piece will look the very same, so the opportunity you will need to discard any of them as a result of variances is reduced. Additionally, because a proofing example is printed on the very same equipment as the product itself, shade proofing is very precise. Any kind of issues with color will show up on the evidence, and therefore it will certainly be feasible to transform it before publishing the entire run.

Getting The 24??media To Work

Digital printing, on the other hand, calls for marginal configuration. This is terrific when you are in a hurry to get your printed products.

This suggests even more requests for digital on-demand print production. Every consumer values a tailored message. Economical, smaller sized batches enable businesses to customize each order.

Digital printing is the best choice for variable data printing, like custom codes and addresses on direct-mail advertising. With electronic printing, it is much less troublesome to make final modifications to your layout. Often the very best form of interaction is not electronic. In these cases, relying upon electronic printing can guarantee these orders have a very little ecological impact.

Some Known Incorrect Statements About 24??media

There is also no requirement to clean the plates after printing. The benefits of digital printing include that there is no waste from added or remaining ink, paper, or chemicals since just what's needed gets published. - for really short runs, electronic printing is the means to go, undoubtedly.

Gone are the days of complex configurations and lengthy turn-around times - digital printing has revolutionised the print industry. The printing world has come a lengthy method since the days of Gutenberg's printing machine. The brand-new normal is streamlined processes and affordable remedies for publishing onto almost anything you can think about.

Report this page